Choosing the right Polymaker 3D printer means matching it with what you need. They provide a wide range of filaments. PLA is easy to print with and comes in many colors, but it can’t handle high heat. If you need something that resists chemicals better, look into PETG. TPU is great for flexible prints that need to move.

If you’ve got more technical needs, there are materials like Polycarbonate and Nylon. These can withstand more heat and are good for bigger, tougher projects. They do need more careful settings though. Tweaking things like retraction can fix problems like blobs in your prints1.

It’s key to check if your 3D printer works with the materials Polymaker offers. Each material affects your final print in its own way. Knowing this helps you choose wisely.

Key Takeaways

- Choose Polymaker filaments like PLA for ease of use and a variety of color options.

- PETG offers robust chemical resistance and is a versatile choice for multiple projects.

- TPU is flexible, making it ideal for applications needing elasticity.

- Advanced materials like Polycarbonate and Nylon are great for high-heat applications but require specific printing settings.

- Adjusting printer settings can help reduce common print issues such as oozing and blobs1.

Understanding Polymaker 3D Printers

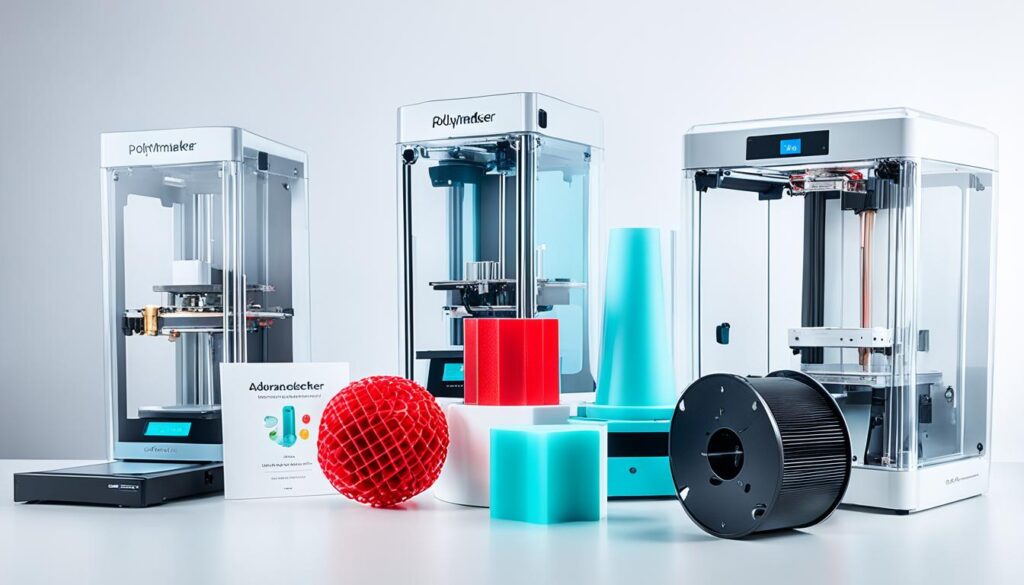

In our search through the Polymaker comparison guide, it’s easy to see the strength of these 3D printers is versatility. They work well with many filaments. This means you have a lot of options to choose from when picking your materials2.

For instance, PolyLite PLA can be found in various colors and finishes, including those that shine in the dark. This is perfect for fun, colorful projects. On the other hand, PLA Pro has more strength than your average PLA, and it comes in cool Metallic colors2. And if you need something even tougher, there’s PolyMax PLA with reinforcement technology. It’s a bit pricier but offers more durability2.

Now, let’s look at some other Polymaker options. PolySonic PLA stands out for its speed. It can print fast and still keep its strength. This makes it great for quickly trying out new ideas. Then there’s PolyLite PETG, an easy-to-use filament that comes in many colors, including some see-through ones2.

If you need something really strong, the PolyMide CoPA might catch your eye. It’s tough, handles heat well, and perfect for tough jobs. And for quality prints and tough parts, the PolyMax PC is a top choice2.

What’s also great is the tech Polymaker uses. Features like Warp-Free™ in the PolyMide™ line lower stress and better part strength. The Layer-Free™ from PolySmooth™, on the other hand, smooths prints with alcohol. These innovations tackle common print problems, leading to better quality and more durable prints. Polymaker shows their commitment to pushing the limits in 3D printing with these special features.

Key Features to Look for in Polymaker Models

To pick the best Polymaker model, look closely at print speed, build volume, and materials it can use. These three aspects are vital for how well and where you can use your 3D printer.

Print Speed

Print speed matters a lot for quick designs. With Polymaker’s PolySonic PLA, you can print as fast as 500mm/s. This means you can finish jobs quickly, great for busy settings3.

Build Volume

Build volume is about how big your prints can be. Check if the Polymaker model can make what you need by its size. Bigger machines can handle large projects but need more room. Make sure to have a clear idea of the space and size you need first.

Material Compatibility

Polymaker printers work with many materials. They handle things like glass and carbon fiber filaments. For these tough materials, they come with special nozzles to last longer. PolySmooth™ is another great choice, needing only 190°C to work and softening at 70°C4. This gives you lots of options for different projects.

| Feature | Details |

|---|---|

| Print Speed | Up to 500mm/s with PolySonic PLA, 29 mm³/s flow rate3 |

| Build Volume | Varies by model; choose based on project size |

| Material Compatibility | Support advanced filaments like glass fiber reinforced Nylon; PolySmooth™ operational at 190°C4 |

Comparing Top Polymaker 3D Printers

Looking at the best polymaker 3d printer, we find important proprietary technologies. Polymaker’s Jam-Free™ Technology stops filament jams by improving heat resistance5. This tech is great for fast printing, ideal for quick prototyping.

Nano-reinforcement tech boosts toughness and flexibility in filaments like PolyMax™ PLA, giving it strong ABS-like qualities52. This makes it perfect for tougher jobs.

Polymaker’s wide range of colors and effects also adds to their printers’ value. PolyLite™ PLA comes in many colors, including special types like Silk and Glow in the Dark2. For specific colors, you might need a tougher nozzle.

PolyMax™ PC excels in strength and impact too, great for serious prototype work2.

When discussing polymaker printers, let’s not forget printing speeds. PolySonic PLA can work at speeds up to 24mm³/s, keeping quality high2. It’s a top choice for jobs needing speed.

| Model | Proprietary Technology | Material Compatibility |

|---|---|---|

| PolyLite™ PLA | Jam-Free™ Technology | Silk, Dual Silk, Galaxy, Glow in the Dark2 |

| PolyMax™ PLA | Nano-reinforcement | High impact strength, ABS-like properties5 |

| PolySonic PLA | High-speed printing | Up to 24mm³/s without negative effects2 |

| PolyMax™ PC | High toughness | Excellent impact resistance2 |

These elements help us find the right polymaker 3d printer for our needs. They guarantee good results and efficient work. This guide is here to help pick the best printer for your project and budget.

Polymaker 3D Printers for Beginners vs Advanced Users

Choosing a Polymaker printer involves knowing what’s best for newcomers or veterans. The selection criteria change depending on the user’s experience and what they’ll be creating.

Beginner-Friendly Models

If you’re new to 3D printing, Polymaker has you covered with easy-to-use models. Their PolyLite™ filaments, especially the PLA, have quickly won over users6. PolyLite™ PLA is a top choice because it’s easy to print and doesn’t need any special tricks, perfect for newbies6.

These models work smoothly with PolyLite™ PLA. They fit various 3D printers and guarantee quality with Ingeo® from Natureworks7. Plus, they’re budget-friendly. Currently, you can get PolyLite™ PLA for AUD $36.95, or on sale for AUD $31.957.

Advanced Performance Options

Advanced users might look at Polymaker printers that can handle tougher materials like PolyMax™ and PolyMide™. These need careful printing and finishing touches like annealing for the best strength, which suits challenging projects. PolyMax™ PLA and PETG start at $69.95, showing they’re designed for top-notch results6.

To get the best from these materials, printers that support them are a must. They’re designed to meet the filaments’ specific needs, ensuring top quality and endurance. They’re the go-to for demanding jobs that need top mechanical strength.

Selecting the Right Polymaker Printer for Specific Applications

Choosing the right Polymaker 3D printer means finding one that does what you need. Whether you’re making art or building complex machines, the printer must fit your work. This way, your creativity or engineering skills can shine through.

Prototyping and Functional Parts

For prototyping or functional parts, you want strong, heat-resistant materials. PolyMax PC fits the bill with its durability. A study by Ernst and Young found that printing electronics could make prototyping 63% faster8. Plus, FFF printers’ accuracy, usually within ±0.5 mm, lets you create precise prototypes8.

Art and Design Projects

Art and design need versatile filaments. PolyTerra PLA stands out with its many colors and finishes. The PLA in PolyTerra is tough, with up to 529 k psi strength at 73°F8. This means your art pieces don’t just look good but last a long time too.

Mechanical and Engineering Applications

In engineering, you must choose printers known for their material strength. PolyMide PA6-CF is often chosen for its mechanical prowess. ABS and PETG are also important. ABS offers about 10 kpsi flex strength8, and PETG has roughly a 5.6 k psi tensile strength8. They’re tough, perfect for challenging engineering jobs. Knowing this lets you pick the right Polymaker printer, whether for art or engineering.

Polymaker Printer Features and Technologies

Polymaker printers stand out for their cutting-edge polymaker printer features. These features boost how well prints come out and how easy using the printer feels. Ash-Free™ Technology ensures no ash is left when printing complex structures. This is perfect for detailed designs. Fiber Adhesion™ Technology makes sure layers bond tightly, enhancing the strength of your prints.

Polymaker also brings us Stabilized Foaming™ Technology. This innovation gives prints a wood-like look. This is done without the challenges of using real wood materials. It helps achieve a stable texture and strength in the print.

Now, let’s look at the wide range of materials that work with Polymaker printers. They show off the printers’ flexibility and broad application areas:

| Material Type | Options | Properties |

|---|---|---|

| PLA | PolyLite PLA, PolyTerra PLA, PLA Pro, CosPLA, PolyMax PLA, PolySonic PLA, PolySonic PLA Pro | Many color options, simple to print2 |

| ABS and ASA | PolyLite ABS, PolyLite ASA | Handles impact well, good for use in parts2 |

| PETG | PolyLite PETG, PolyMax PETG, PolyMax PETG-ESD | Resistant to chemicals, flexible2 |

| TPU | PolyFlex TPU90, PolyFlex TPU95, PolyFlex TPU95-HF | Very stretchy, flexible2 |

| Polycarbonate | PolyLite PC, PolyMax PC, PolyMax PC-FR, PolyMax PC-ABS, PolyMax PC-PBT | Withstands high heat, tough2 |

| Nylon | PolyMide CoPA, PolyMide PA6-GF, PolyMide PA6-CF, PolyMide PA612-CF, PolyMide PA12-CF | Very strong, long-lasting2 |

| Unique Materials | PolySmooth, PolyCast, PolySupport | For specific needs, for support2 |

| Special Effect Filaments | PolyLite PLA-CF, PolyLite PLA Glow, PolyLite Galaxy PLA, PolyTerra PLA, PolyLite Silk PLA, PolyTerra Marble PLA, PolyWood PLA | Provides flat, silken looks, shines in the dark, mimics wood5 |

With a variety of materials and cutting-edge tech, Polymaker printers can handle many types of projects. Whether you want your prints to look beautiful or to be very strong, Polymaker’s polymaker printer features are here to help. They speed up the process from your idea to a real print in your hand.

User Reviews and Feedback

It’s essential to know what people think about Polymaker 3D printers before buying one. User reviews and expert opinions give us the lowdown on how well these machines work. This info helps folks pick the best printer for their needs.

Customer Testimonials

Customers love the Polymaker filaments, especially the 1.75 mm type, because it leads to smooth printing and fewer jams9. They point out that these filaments work at a wide range of temperatures, from 190˚C to 230˚C, making them versatile9. Buyers also mention the 1 kg filament pack lasts long, so they can print more without needing to buy more soon9.

Expert Reviews

The pros dive deep into what makes Polymaker printers stand out, like the Polysher™. They say using 70–90% isopropyl alcohol in it is key for smoother prints10. This method hides the print’s lines well and only takes 30 minutes for a sleek finish10. They also mark the Polysher’s price as $299, something any buyer might want to know10. Plus, they note that while PolySmooth filament is pricier than regular PLA, it gives prints a pro look10.

Both user and expert reviews offer a full picture of Polymaker printers. They cover how trustworthy these printers are, their print quality, and how much users like them. Getting this mix of insights helps everyone make a solid choice.

Polymaker 3D Printers polymaker how to choose

Choosing a Polymaker 3D printer means knowing what you’ll print and what each model can do. Polymaker’s printers handle many different materials, giving you lots of options. They offer materials from PLA to Polycarbonate, each with its own strengths like impact resistance or flexibility2.

If you need heat and UV resistance, consider ABS and ASA filaments2. PETG is great for tough, durable parts2. And for flexibility, TPU comes in various types to meet your needs2.

For the toughest materials, look at Polycarbonate and reinforced Nylon. They’re strong against impacts and heat2. New tech like Fiber Adhesion™ improves how strong the layers are, making the prints even tougher11.

The Nano-reinforcement in PolyMax makes them very tough11. Polymaker also developed Stabilized Foaming™ for PolyWood. This tech makes the print look like wood and act like it, but without the issues of wood filaments11.

Polymaker’s PLA line is wide, catering to different needs. PolyLite PLA is perfect for beginners with its quality and ease of printing5. PolyTerra PLA+ offers more strength and impact resistance. PolyMax PLA is the strongest, with the toughness of ABS but made from PLA5. They also have sustainable options, mixing PLA with natural ingredients to lower plastic use and give unique results5.

Knowing the details and materials of Polymaker’s printers helps make the right choice. Whether you’re into quick prototypes, art projects, or engineering, choosing the right Polymaker printer ensures your work meets your high standards5.

Conclusion

We’ve explored a lot in this guide to Polymaker’s 3D printers. We looked at different materials, like PLA, ABS, and special ones like PolyMax and PolyFlex12. Polymaker also cares about the environment. They make a recycled material called PolyLite PLA, keeping our planet in mind12. People love Polymaker’s filaments because they are always the right width and make prints with great quality and stick together well12.

Handling moisture in filaments is crucial for good prints. For instance, PVA gets too wet fast, so you might need something like a Ninja Cooker or a drybox to keep it dry13. On the other hand, filaments like Amazon Basics white PLA can stay good for printing even after being wet for a long time13.

Polymaker’s fast printing with PolySonic PLA is a big deal. It lets you print at up to 500mm/s without the print quality dropping, avoiding a common issue called the shark skin effect3. A test with the Anycubic Kobra 2 Pro showed it can make a great benchy in just 13 minutes, really handy for quick design tests3.

For anyone, whether you’re new or a pro, there’s a lot to learn and consider when picking a 3D printer. This guide is here to help you make a smart choice. We hope it’s given you all the info you need to find the perfect printer for your projects and dreams.

FAQ

How do I choose the best Polymaker 3D printer for my needs?

What are the key features of Polymaker 3D printers?

Which Polymaker 3D printer models are best for beginners?

What are the best Polymaker 3D printers for advanced users?

How do I select the right Polymaker printer for specific applications like prototyping and art projects?

What proprietary technologies are used in Polymaker 3D printers?

What do user reviews and expert feedback say about Polymaker 3D printers?

Source Links

- https://us.polymaker.com/blogs/3d-printing-tips/blobs-and-oozing

- https://us.polymaker.com/blogs/finding-the-right-filament/material-comparisons

- https://www.3djake.ie/info/guide/high-speed-printing-and-polymaker-polysonic-pla

- https://www.3dprintingsolutions.com.au/User-Guides/how-to-3d-print-polysmooth-filament

- https://www.3dprintingsolutions.com.au/Filament/Polymaker-PLA

- https://www.3dprintingsolutions.com.au/News/christmas-buyers-guide-for-2019

- https://www.3dprintingsolutions.com.au/Store/Australia/polymaker-polylite-pla-cold-white-1kg-175mm

- https://www.designworldonline.com/how-to-select-the-right-3d-printer/

- https://www.sliceengineering.com/products/polylite-pla

- https://www.hackster.io/news/review-polymaker-s-polysher-makes-your-3d-prints-shiny-and-smooth-b28f8cd4eaac

- https://us.polymaker.com/blogs/finding-the-right-filament/polymakers-technologies

- https://www.in3dtec.com/exploring-the-top-3d-printing-filament-brands-for-exceptional-prints/

- https://forum.prusa3d.com/forum/general-discussion-announcements-and-releases/pla-gets-brittle/